Alrighty. Making the nut is pretty crucial. Very small piece of the overall instrument, but its absolutely critical to the sound and playability of the guitar.

I use unbleached bone blanks.

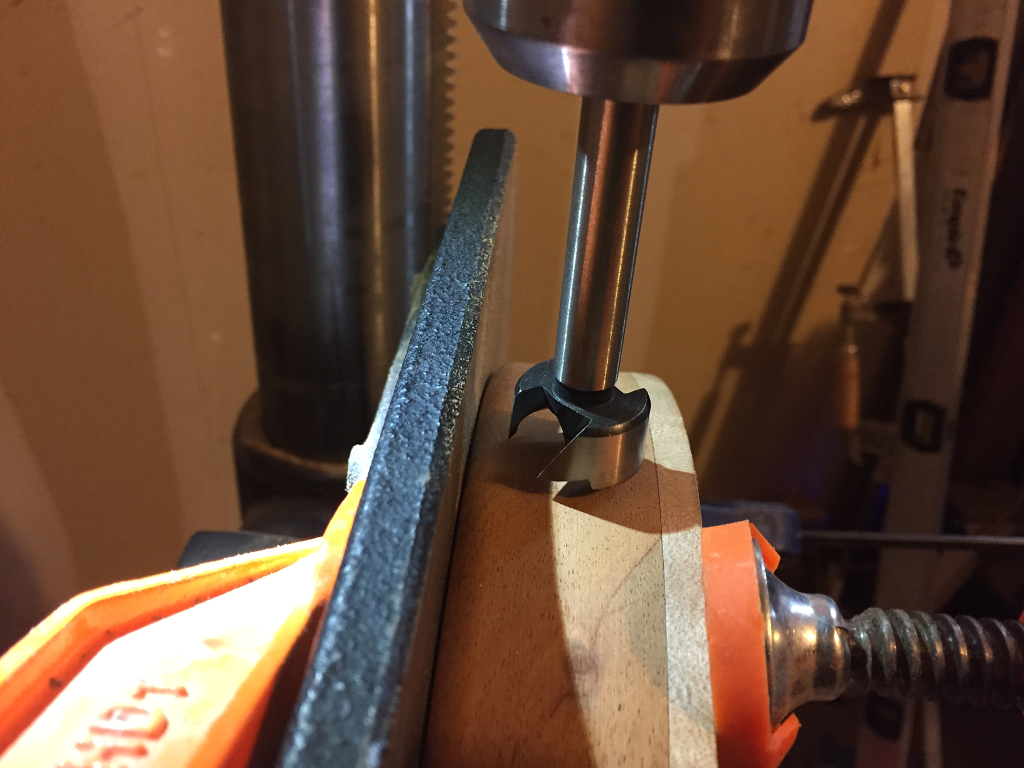

Grind to roughly the right size and shape. This means the bottom of the nut, and the side that contacts the fretboard have to be perfectly flat, and the surface the nut sits on also has to be perfectly flat. This allows the nut to sit solidly and squarely on the neck. Then once those faces are prepared, the top and back are ground down to roughly the final dimensions using a disk sander. Then the nut is fit into place and held with just one teeny drop of CA glue to keep it solid while working on it.

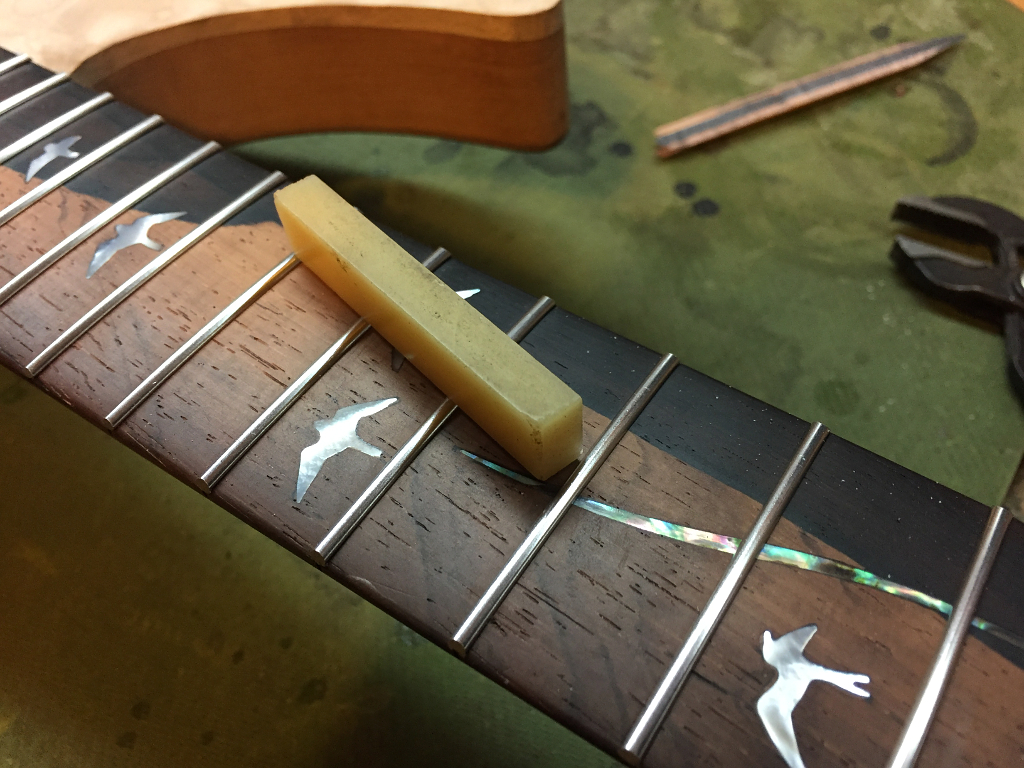

I use a string spacing guide from Stewart-Macdonald to calculate the slot positions. First I mark the outer two slots exactly 1/8″ in from either side, then find the appropriate spacing on the guide and mark the rest.

I use gauged nut slotting files, so each slot is custom-fit for the string that will be in it. I always go a with .010-.046 gauge strings. I use the file thats either the exact size of the string, or the next size up if theres not an exact match.

then I use a string action gauge to determine exactly how deep to cut each slot. Once the slots are all cut to the right depth, a bit more of the top is sanded down so that each string is just deep enough into the nut to keep it firmly in place, but not actually below the top.

Once the nut is perfect, then I smooth the whole nut and add a nice luster to it by sanding the whole thing up to about 3000 grit paper.