Rough cutting the neck

This is my 8″ jointer. Its used to make one side of a rough-cut piece of lumber perfectly flat. It’ll take off any cupping or warping caused by the natural seasoning process of wood.

Very important to set the fence at exactly 90 degrees from the surface. Once the main face is flat, you flatten one edge while keeping the previously flattened face against the fence. This gives me two perfectly flat, straight faces at exactly 90 degrees to each other.

Unlike when doing rough carpentry, framing, etc, close will never be good enough when building an instrument. Surfaces much be perfectly flat and smooth, mating faces flawless, angles right on the money.

You can see theres a slight cup to this board running end to end. Note how the long edges are on the bed, but on the near end you can see its up off the bed. As it dried the board cupped and warped a little.

I flip it over after a few passes to see how I’m doing (I set my jointer to remove just a sliver with each pass) you can see its taking the outside edges off little by little

Flip it back over and continue making passes until its perfect flat end to end and side to side. This took about 16 passes or so, to give you an idea how thin a shaving comes off with each pass

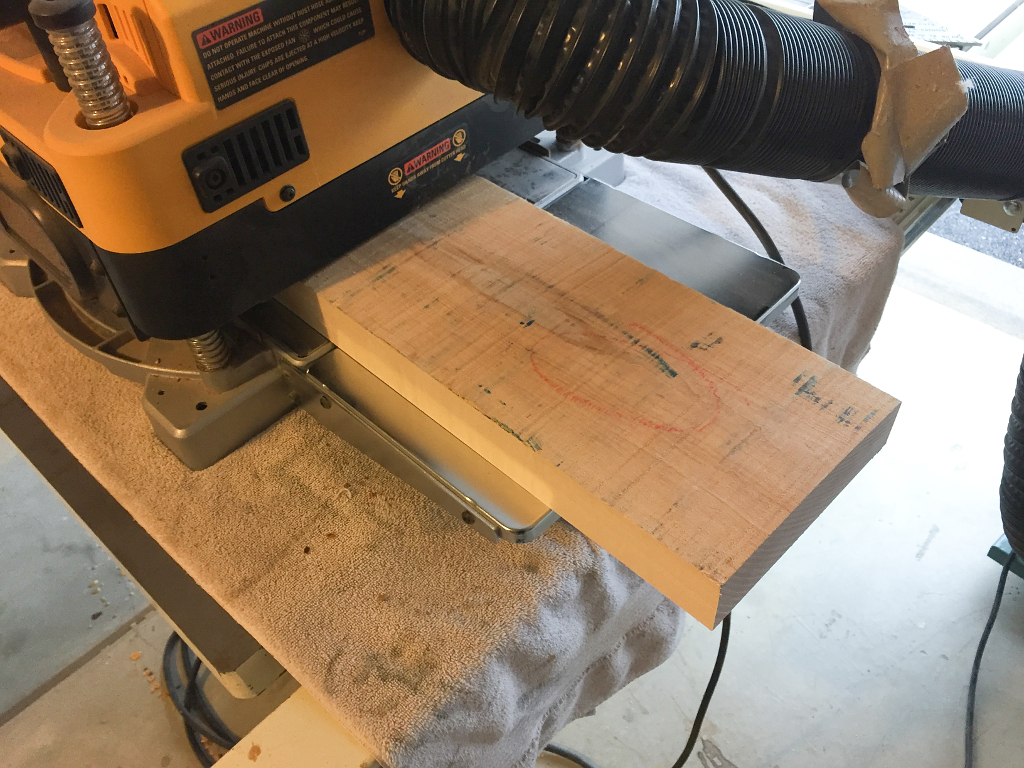

Next we run it through the planer with the freshly flattened side facing down. This is the opposite side from the cupped face so its actually convex. The planer will take off the excess from the top, again in multiple passes until the top is flat. now the board is perfectly flat top and bottom, exactly the same thickness end to and and side to side, with one edge perfectly flat and 90 degrees to the faces.

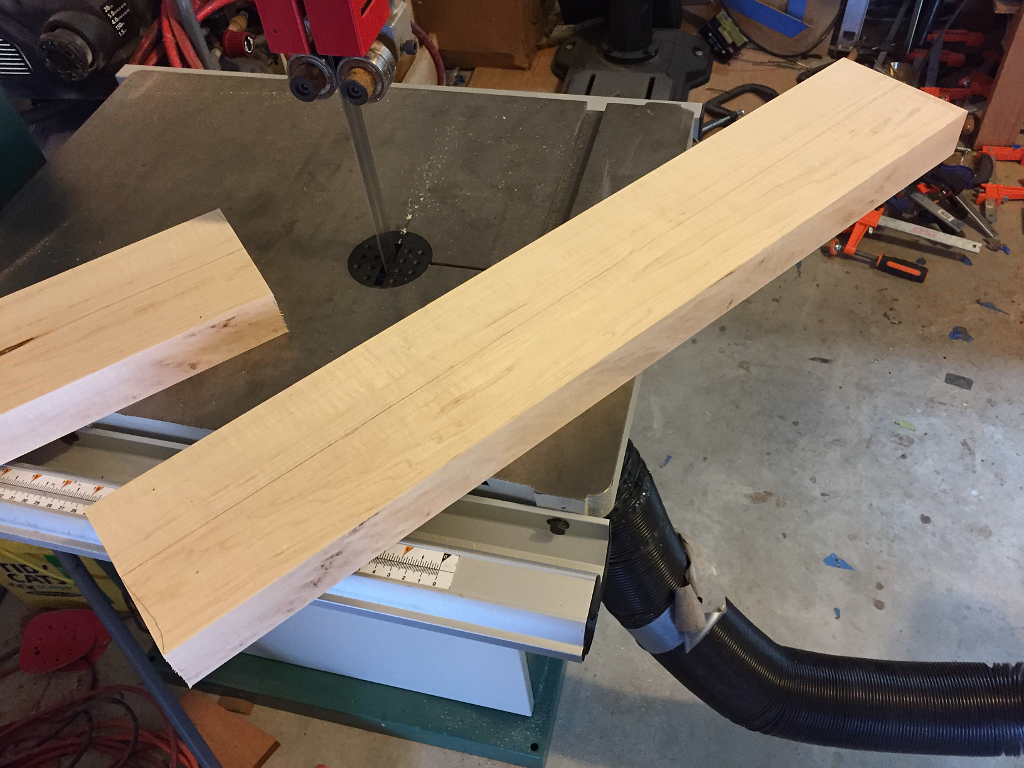

Then onto the table saw. The flattened edge runs along the fence, I trim the excess width, and leaves me with the board all flat and straight and ready to work with.

Then “re-saw” it on the band saw leaving me with a perfect 1″ thick neck blank. 1″ is still thicker than I need, but there are a lot of stresses and tensions in wood and removing large amounts of wood can relieve some of these stresses. What this means that in the next week or two, having been removed from the middle of a much larger, thicker piece of wood, this guy might move a little more, so I leave it a bit thicker than the final dimensions. I’ll let this sit a couple weeks and then repeat the same procedure with jointer and planer to get rid of any warpage. the result will be a neck blank that wont warp over time because its in a state of natural equilibrium…

Just tracing the neck outline with my template to show where the neck is in this piece of maple 🙂