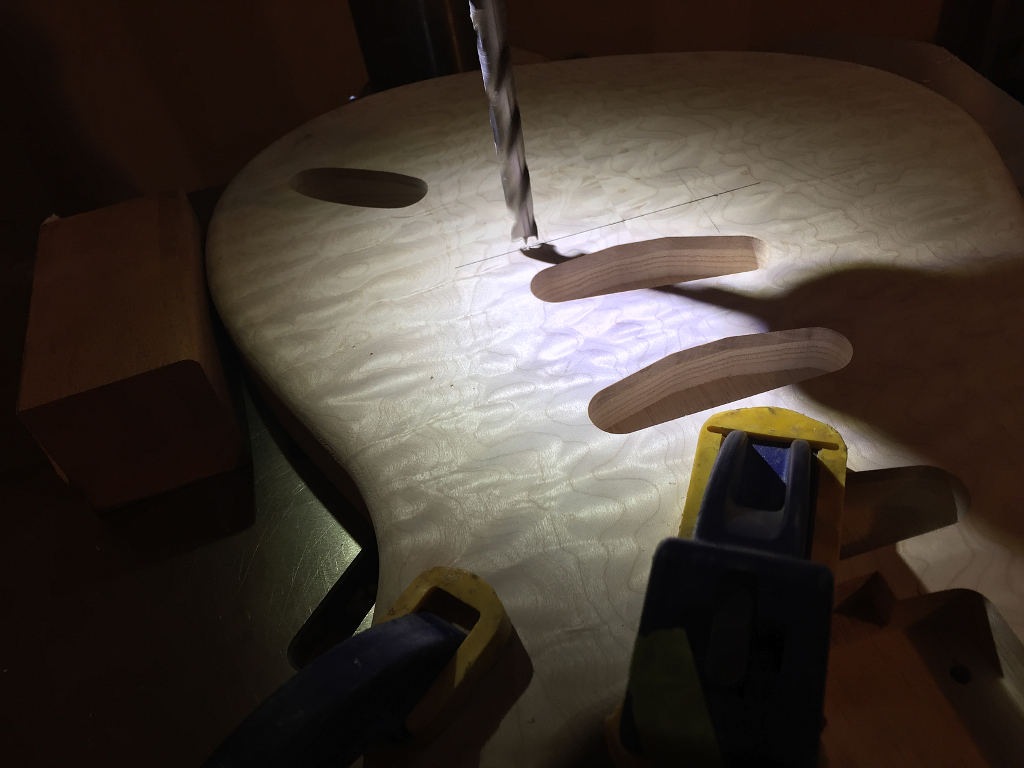

Mounted the locking nut, because the nut it the key measurement point for determining the exact placement of the tremolo posts

Right…about…here!

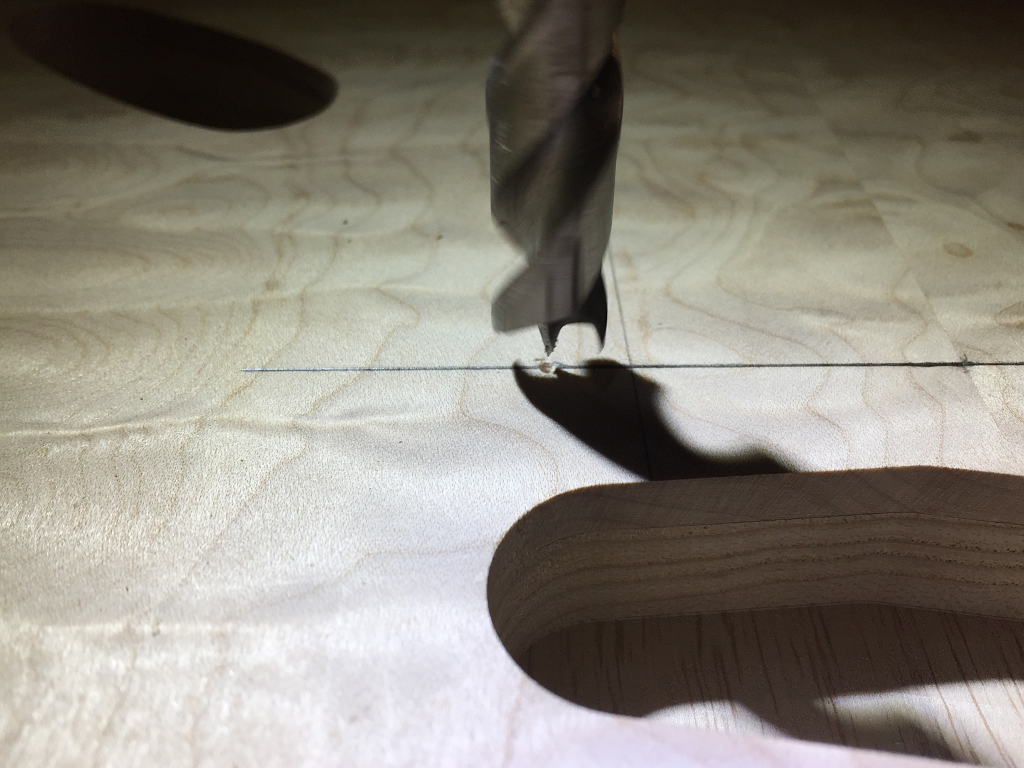

The post holes will be drilled along this line, centered and spaced precisely. This is critical to the proper functioning of the tremolo as well as being able to set the intonation properly.

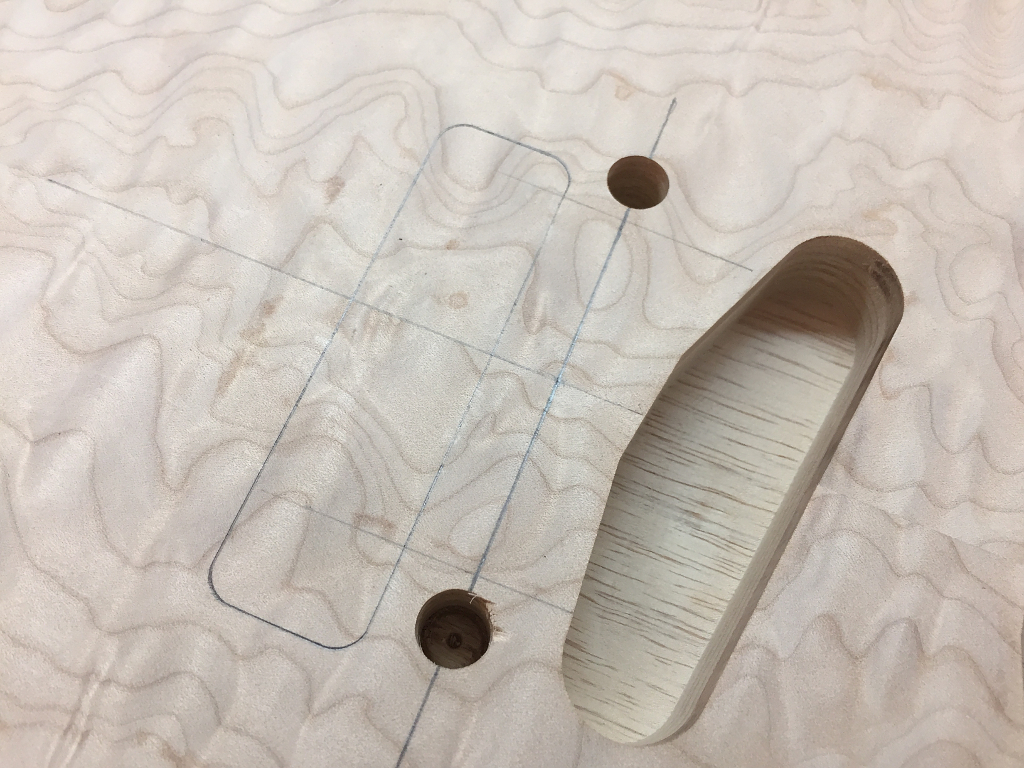

With the holes drilled I can now mark out where the trem recess will be.

A hole is drilled through from the front in one corner of the area where I laid out my lines for the trem route. This gives me a precise location from where I can lay out the spring cavity on the back.

As with the pickup routes, a lot of the wood can be removed with the drill press and forstner bit. Saves wear and tear on the router and allows for a cleaner final result.

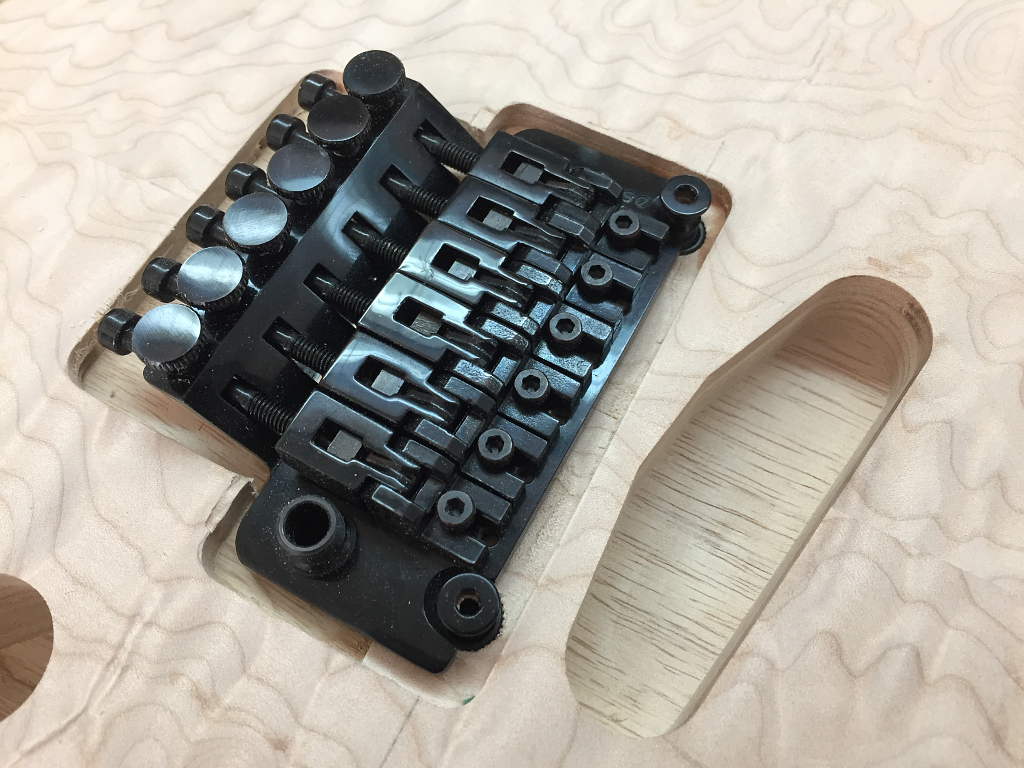

I press the bushings for the bridge posts into the holes using my drill press.

With the posts screwed into the bushings I can place the bridge against the posts to make sure I did everything right. I did 🙂

Test fitting the tuning machines…

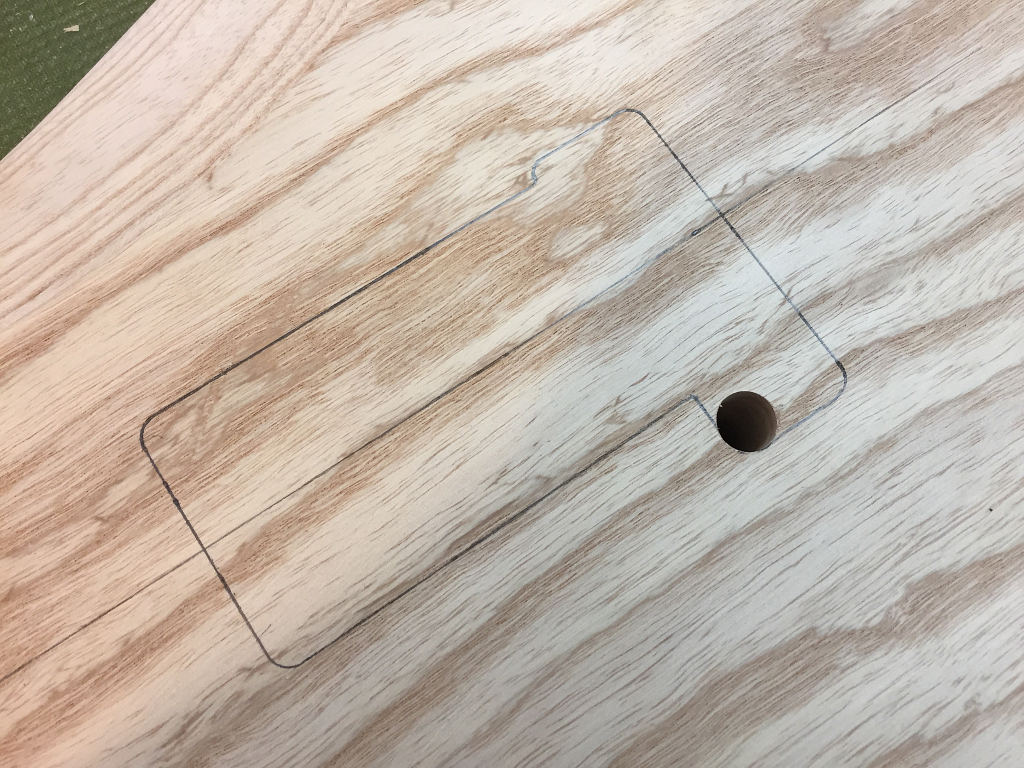

Using a routing template to locate where the control cavity will go

Template and router finish the cavity.

I use my dremel to cut the slot for the blade switch.

Last step is cutting the cover recess.

That concludes the build part of the project.